Floral Growers

Retail Produce & Floral Coolers

Airocide PPTTM Perishables Preservation Technology

Airocide PPTTM photocatalytic air purifiers contain the same NASA-developed technology that is used in a variety of Airocide product lines. In addition to serving the food safety industry as well as in floral and perishable preservation Airocide technology has been developed to kill/remove/eliminate airborne pathogenic and non-pathogenic microorganisms in vegetative and spore states (bacteria, mold, fungi, viruses and dust mites), allergens, odors and harmful volatile organic compounds (VOCs) in air in a variety of commercial, government and residential market applications including the medical healthcare industry (Airocide is listed as an FDA Class II Medical Device).

Summary

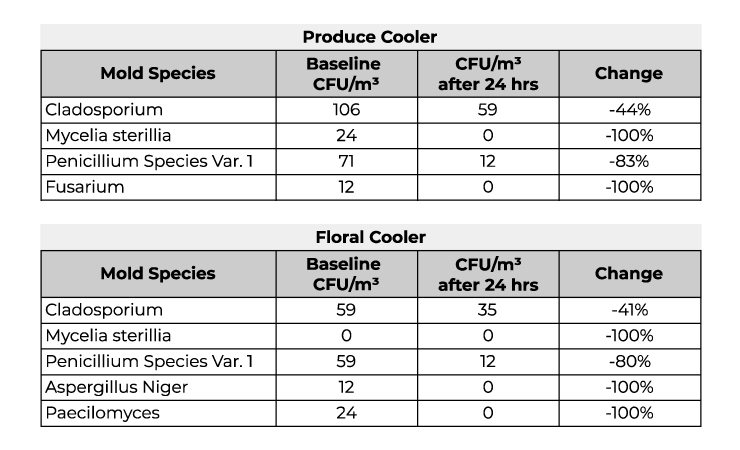

A clinical study of the Airocide PPT airborne pathogen killing technology was conducted in the produce cooler and floral cooler of a national retail grocery store. The data supports the hypothesis that airborne mold and bacteria levels would be lowered after continuous operation of the Airocide PPT air purifying system. The results show a range of 41% to 100% decrease in levels of specific airborne mold species in the produce cooler. In the floral cooler mold level decreases ranged from 44% to 100%.

Conditions

The test site is approximately ten (10) years old. The walk-in produce cooler is located in the back of the store and is 136 m³ in volume. Temperature in the cooler was maintained at 4 °C at the time of the test. On day 1 of testing the store received a double shipment leaving many pallets and boxes stacked outside the already full cooler. The produce cooler door remains open over 50% of the time during the day and is equipped with plastic strips that provide access while maintaining some air blockage. Two (2) employees are scheduled to work in the produce department between 6 am and 7 pm. From 7 pm to 6 am the produce cooler doors were closed. The 28 m³ floral cooler is located in the front of the store. The temperature was 3 °C during the tests. During the test period the store was running a sale on roses and the display areas and small storage room were full.

Protocol

The study was conducted during two typical business days. On day 1 of testing (September 17, 2003) four (4) air samples were taken in the produce storage area and four (4) samples were taken in the floral storage area before the Airocide PPT air purifiers were turned on. These samples established the baseline. On day 2 of testing (September 18, 2003) the same eight (8) samples above were taken after one air purifier (GCS-100) was operating in each cooler for 24-hours. Air samples were taken with a impingement air sampler (similar to the Andersen N6 sampler) on 15 x 100 mm plastic petri dishes. Each of the three (3) stations were sampled using one (1) Potato Dextrose Agar plate (mold/fungal growth media) and one (1) Rose Bengal Agar plate (bacteria growth media). All agar plates were exposed to 28.3 l/m of air for 3 minutes. The results were measured in colony forming units (CFU) per cubic meter of air (CFU: the number of viable bacteria or fungal cells in a sample capable of reproduction).

Results

The tables below show examples of specific mold species that showed significant decreases in 24 hours. Decreases ranged from 41% to 100% in the produce cooler. In the floral cooler mold level decreases ranged from 44% to 100%.

Floral Pre-Coolers

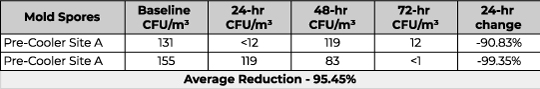

The table below shows airborne mold reduction at two sites inside the Pre-Coolers of 90.83% and 99.35%, or an average of 95.45% in 72 hours. A significant reduction was realized in just 24 hours.

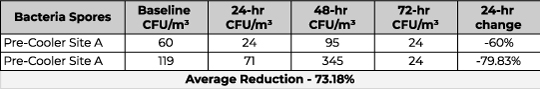

The table bellow shows airborne mold reduction at two sites inside the Pre-Coolers of 60% and 79.83%, or an average of 73.18% in 72 hours. A significant reduction was realized in just 24 hours.

Floral Cooler & Store Facility

Results

Table 1 shows airborne reduction inside the store facility and the cooler of 99.99% and 100% or an average of 99.99% in eleven (11) days.